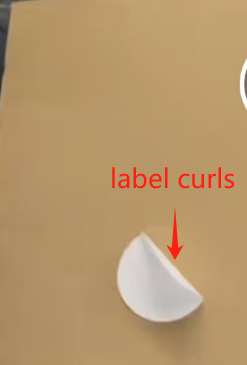

The reasons for curling after labeling are:

1. Label problem cause curling after labeling: mainly due to insufficient label viscosity and excessive tension after label coating with film.

2. curling after labeling caused by Substrate:

a. The substrate is round and has a small diameter

b. The substrate surface has low-energy,like PE bag

c. The substrate surface is too rough

d. The substrate surface is not clean(water, oil,dust or filling liquid overflow on the surface).

3. curling after labeling caused by the labeling process: incomplete press, insufficient press pressure, inappropriate press device selection, etc.

- Environmental causes curling after labeling: During labeling, storage and substrate usage, the temperature changes significantly, or the temperature is too low, resulting in insufficient viscosity.

Following pls find our suggest solution:

Solution to Label problem cause curling after labeling:

A. If the label is not sticky enough, we can increase the coating amount of glue to increase the stickiness. If the stickiness is still not good enough, we need to choose special high-viscosity glue.

B. For label surface with film,we should control well the tension to avoid label curling after labeling.

Solution to curling after labeling caused by Substrate problem:

A. The Substrate surface needs to be cleaned before labeling, and the water on the surface needs to be completely dried. We also need to prevent filling liquid overflowing and affecting the glue performance.

B. If the bottle is round and the diameter is less than 30mm, we need to choose high-viscosity glue, thinner surface material, and softer surface material.

C. If the Substrate surface is low-energy, corona treatment or special glue is required.

Solution to curling after labeling caused by the labeling process:

We need to press completely and sufficient pressure,we can choose a suitable tool to do this.

Solution to curling after labeling caused by temperature:

In order to prevent the label from curling due to environmental problems, we need to pay attention to the labeling temperature and the use temperature of the label. The label needs to be labeled at the appropriate temperature and left for 24 hours, at which time the glue will fully work and stick firmly to the product. We will then transfer it to other warehouses, and there will be no problems within label application temperature.