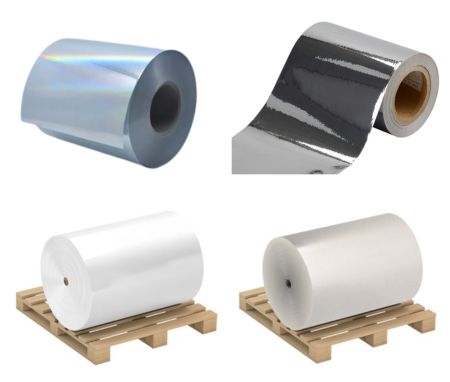

What is PE label

It is a kind of label and facestock is PE film which is coated on the surface and with adhesive on the back.

PE label structure

PE label structure contains facestock,adhesive and liner

PE film label advantage

Advantages:

1.It has good tensile performance and can be used in soft bottles.

2. Non-toxic, environmentally friendly.

3. Waterproof, oil-proof, and can maintain a certain degree of flexibility.

PE Label application

1. Cosmetic,food, beverage packaging, such as bottles, jars, etc.

2. Cleaning products, such as detergents, washing liquids, etc., because of its waterproof and chemical resistance

PE Label storage suggestion

PE Label shelf life:12 months

PE Label storage suggestion:

This material must be stored at a temperature of 23±2ºC and 50±5% of Relative Humidity.

Storage area must be dry and clean.

Keep the material in the original packaging when not used in order to protect it from dust and contamination.

Do not expose to direct sunlight or heat sources.

Whether it is during transportation or warehouse storage, the product should be placed vertically.

If you still have any question pls contact us for professional advise.