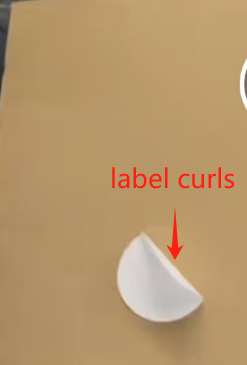

According to our experience, there are following reasons:

1. The blade is not sharp enough and the glue is not completely cut off. For this case, we can solve the problem by replacing a new blade.

2. The glue is completely cut off, but the fluidity of the glue increases when the temperature is high. If the die-cutting machine and the scrap rolling machine is far away, the glue flows back and sticks together again, which will also cause label missing when rolling the scrap . At this time, we only need to shorten the die-cutting and scrap rolling machine distance.

3. The low peeling off force of the self-adhesive label causes label missing. Here is the main reasons for the low peeling force are:

A.Label material factory set a low peel off force. In this case, the supplier needs to adjust the material and adjust the peel off force.

B. The storage time of the self-adhesive label material is too long, and the glue and silicone oil performance changed. We suggest storage time of self-adhesive label material is less than one year.

C. In winter, the temperature is too low, and the glue hardens, resulting in a decrease in peeling force. In this case, it is necessary to adjust the storage and processing temperature of the self-adhesive label.

4. The facestock thickness and stiffness is also important, thicker and stronger facestock of the self-adhesive label material is easy to miss when making small-sized labels. In this case, we need to change self-adhesive label material types.

We are a professional label material manufacturer, if you have any problem welcome to discuss.