label curls?Let me help you.

Date: 2025-02-10 Categories: 新闻中心 Views: 143

We hear many clients complain that label curls,here we explain why this happen and how to solve it.

A.If labels curl after we do die-cutting, this is because we didn’t control the printing and die-cutting workshop temperature and humidity well. We need to control the temperature between 20-25℃ and the relative humidity at 50%

B.If label curls immediately after labeling, it is generally caused by insufficient sticky performance of the adhesive, or your label material stores too long time,or labeling workshop temperature is too low temperature. Our solutions are:

1. Control well the labeling workshop temperature,temperature too high or too low will have problems.

2. Don’t store label material more than 1 year.

3. Test label material before mass production.

4. If label is used for carton and the surface is uneven,we need to increase amount of glue on labels.

C.If label curling start 24 hours after labeling, this is mainly because inappropriate selection of self-adhesive materials, poor cohesion, unreasonable use by customers, etc.

1. Choose the right self-adhesive material. Self-adhesive for small bottles should choose strong adhesives, whose adhesion on the bottle body should be much greater than the elastic force of the label surface material itself to resist deformation, so as to ensure that there is no warping after labeling. For round, curved and other back stickers, we try to choose PE self-adhesive materials, which are soft and have elongation properties.

2. Poor adhesive viscosity causes labeling to warp

Some adhesive sticky performance is not stable, that means the glue performance is very good at first, but it can’t keep for a long time. So labels will curl after labeling.

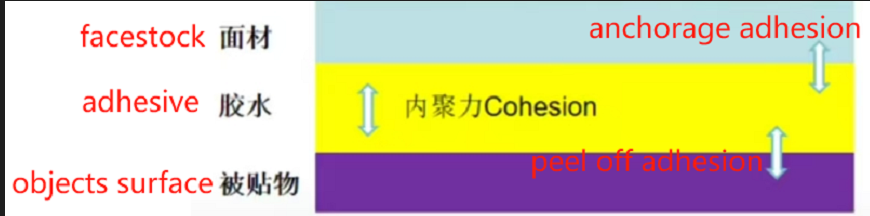

3. Poor adhesive cohesion causes labeling to warp

Generally speaking, if the self-adhesive label does not curl after 24 hours of labeling, there will be no problem. But sometimes the label curls after 2-3days of labeling, this is usually due to insufficient cohesion of the adhesive, if we find some of the adhesive remains on the label, while some other glue remains on the surface of the bottle.,this is the cohesion problem.we can ask the supplier to change to a better glue or need to change the self-adhesive material supplier.

4. bottles are not clean on surface, no self-adhesive labels can be firmly attached to surfaces with water, oil, or dust, and the bottle should be kept dry and clean.